MARPOL approved NOx Analyzer

MES 1001 MARPOL

Precise, continuous and approved measurement

MES 1001 MARPOL enables precise and continuous measurement of the environmentally harmful gasses NOx, directly in the exhaust pipe, which ensures fast and accurate measurement.

Extra value created for operator w. MES1001 MARPOL

Value created for shipowner:

- Shipowner will avoid spot checks incl. OPEX gained for:

- no travel cost to/from vessel

- no rental equipment for spot checks

- MARPOL sensor compared to spot check: Shipowner will have new OPEX cost for UV lamp 14-24 month depending on usage profile of vessel (“Lamp OPEX” lower than “Spot check OPEX”).

- Shipowner obtains reduced ownership cost (lower OPEX) though HW w. reduced air flow to sensor.

- Shipowner meets MARPOL regulation (still scheme B approval).

- All technical advantages from normal version MES1001 still valid:

- Monitor SCR performance and possible with ammonia slip/early warning of SCR maintenance

- Avoid build-up of ABS (Ammonium BiSulfate)

- Optimize urea dosing in closed loop SCR

- Optimize NOx output

MARPOL is the same basic design that MES1001 but with a possibility for calibration.

MES1001 MARPOL extra features compared to normal MES1001 CEMS:

Hardware additional needed:

New and larger Air Block w.:

Extra valves for calibration process

Pressure regulator added

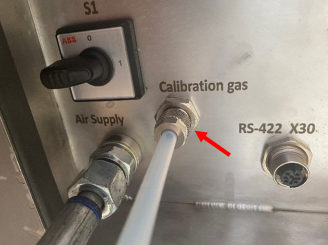

Calibration connection on MARPOL version sensors for span gas connection.

Picture of calibration connection on the MES1001 MARPOL

Production: Test specification changed:

Wind tunnel test

Electric components global price hike

Factory calibration certificate per sensor issued for avoiding commissioning calibration at installment.

R&D extra certification process for MARPOL.

Download material

Here you can download some files related to this product.